Series F2 Electromagnetic Separators

The S.G. Frantz Series F2 Electromagnetic Separators utilize magnetic background fields of approximately 2,500 gauss. The standard water-cooled model can handle product temperatures up to 176°F (80°C), while special thermal insulated units can handle product temperatures up to 400°F (205°C).

The F2 series is designed to separate fine ferromagnetic particles under difficult processing conditions, with background magnetizing fields of at least 2,500 oersteds measured in the empty separating chamber, and well above 2,500 oersteds with the matrix in place — more than twice that of models in the F1 series.

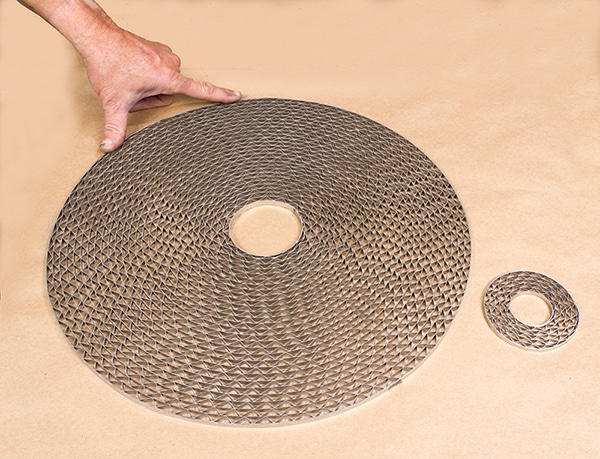

The background field induces a field several times more intense in the collecting elements, with a high-field energy gradient H(dH/dX) at the collecting edges of a standard matrix element fabricated of steel ribbon 1/4″ in width and 0.02″ thick calculated as 7.2 x 1011 gauss2/cm (assuming that the field induced in the steel near the edge is about 8,500 gauss, as measurements indicate).

Series F2 Electromagnetic Separators for Dry Materials

Our Series F2 Electromagnetic Separators for Dry Materials are designed for separating fine ferromagnetic particles present as 1% (weight) or less of the material to be processed. The standard vane type grids are normally utilized for dry material separation. However, for moderately free-flowing materials, we can manufacture a unit that utilizes the same proprietary grids normally used for wet separations. Matrices comprised of wet-type grids have many times the cumulative length of collecting edges than those found in vane-type grids, allowing for better separation. With a unique assembly of grids and a different vibration pattern, such materials can be more effectively processed. A single pass through a matrix of wet grids is equivalent to several passes through a matrix of vane-type grids.

Magnetic background fields measured in the empty separating space (with pole pieces, but without the matrix in place) are approximately 2,500 gauss. Average background magnetizing field measured in the separating chamber with the pole pieces and matrix in place is 3,790 gauss, more than three times the background field intensity of the F1 units. Magnetic fields at the matrix edges, where separation occurs, are nearly 23,000 gauss at the upper edges of the vanes and over 19,500 gauss at their lower edges.

HOW THE F2 ELECTROMAGNETIC SEPARATOR FOR DRY MATERIALS WORKS

- Material is fed into a hopper or hub.

- Material is processed through a stack of alternately inclined parallel grids, pouring over each vane onto the face of the grids below (if wet-type grids are used, material is processed straight through, pouring over multiple edges).

- Collecting edges attract and hold the ferromagnetic particles.

- Material is discharged through the bottom hub (on both units).

TYPICAL APPLICATIONS FOR OUR F2 DRY MATERIAL SEPARATORS

Our F2 Dry Materials Electromagnetic Separators are commonly used in: • Ceramics • Pharmaceuticals • Chemicals • Food Processing • Health and Beauty • Any Dry Granular Material or Powder

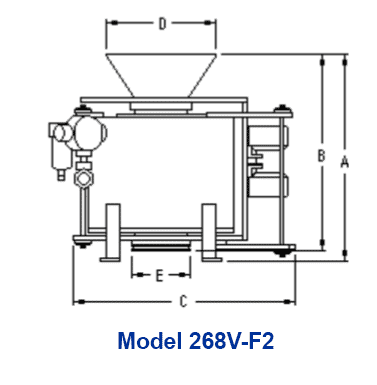

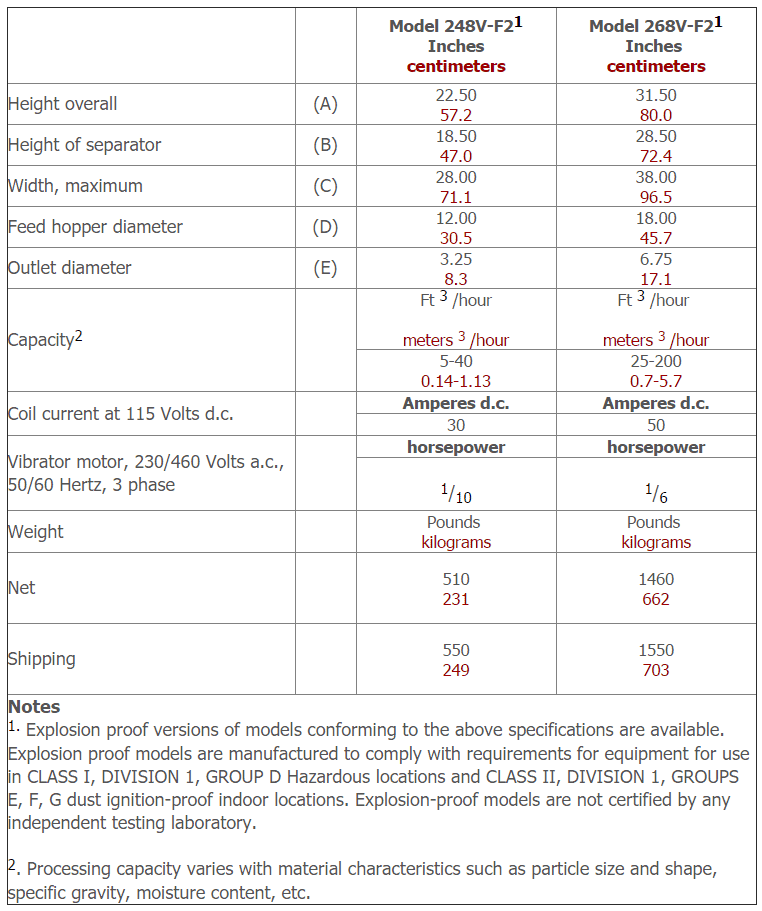

F2 ELECTROMAGNETIC SEPARATOR FOR DRY MATERIALS SPECIFICATIONS

Contact us today to learn more about S.G. Frantzor any of our Electromagnetic, Permanent Magnet and/or Laboratory Separators.