Series F1 with Vane-Type Grids

General application: Series F1 units for dry processing are designed for separating fine ferromagnetic particles present as 1% (weight) or less of the material to be processed.

Maximum product temperature: All listed Series F1 models: 150°F (66°C); special Series F1 models with thermal insulation for higher product temperatures are available.

Field intensity, field gradient and energy gradient: The F1 Series is designed for maximum economy consistent with effective separation of fine ferromagnetic particles. Background magnetizing fields measured in the empty separating chamber (with pole pieces but without the matrix in place) are over 700 Oersteds in water-cooled models and over 500 Oe in air-cooled models. With the matrix in place the background field increases substantially.

The background field induces a field several times more intense in the collecting elements. A high field gradient is provided at the collecting edges; the dimensions and orientation of the elements are essential to these high gradients. Assuming that the field induced in the steel is about 8,900 Gauss near the upper edges of vanes and 5,800 Gauss near their lower edges, as measurements indicate, energy gradient (HdH/dx) is about 2.45 x 109 at the upper and 8.90 x 108 Gauss2/cm at the lower edges of the vanes.

Materials of construction: Product-contact parts of standard units are cast gray iron and stainless steel, types 304 and 430. Special high power units with product contact parts made of stainless or nickel plated steel are available.

Matrices: The standard matrix is a stack of grids with inclined parallel vanes. The inclination of the vanes is reversed with each grid, to guide the material through the matrix in a zigzag course. As it pours over a vane edge and falls on the face of the vane below, the material is turned over and broken up again and again. Vane faces retard the flow and vane edges, where magnetic flux is concentrated, attract and hold the ferromagnetic particles.

Standard grids are of welded steel or cast iron. Special coatings can be supplied to aid the passage of difficult materials. A choice of vane spacing and vane width is available. Nicrobrazed or nickel-plated grids are also available.

In the assembled matrix grids are spaced and cushioned by rubber rings at the outside rim. Special white rubber rings are supplied for processing pharmaceutical and food products.

Suspended models: The separator hangs on four aluminum rods with elastomer bushed connections at both ends to permit lateral motion under vibration.

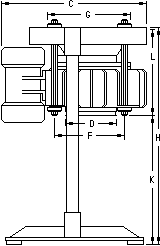

Floor models: With a floor stand and a frame from which the separator is suspended, the floor model can be moved to any location in the plant. Standard models have a feed hopper attached to the top.

Vibration: All models have an eccentric weight vibrator attached to the casing. Vibration can be adjusted to impart the motion required to aid passage of the material. Hubs are provided for attachment of a feed sock at the top and a discharge sock at the bottom. Installation in this manner permits the separator to vibrate freely in a closed system