F1 Series- Electromagnetic Dry Separators

Series F1 electromagnetic dry separators can be configured with either Vane Type Grids or Wet Type Grids. Series F1 electromagnetic separators have efficiently removed fine ferromagnetic particles from a wide range of dry granular materials and powders for over 65 years. They provide economical solutions under many processing conditions. Magnetic background fields measured in the empty separating space (with pole pieces, but without the matrix in place) are over 700 Gauss in water-cooled models and over 500 Gauss in air-cooled models. Magnetic fields at the matrix edges, where separation occurs, are several times higher.

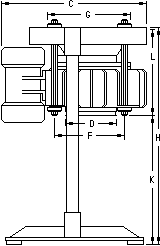

Models With Vane-Type Grids: Series F1 electromagnetic separators with vane-type grids have been the standard for efficiently removing fine ferromagnetic particles from a wide range of dry granular materials and powders for over 65 years. Grids are made of cast iron or welded steel in various opening sizes. They can be plated or coated to accommodate a wide range of processing conditions. Separator models are available for suspension from plant structures or from a floor stand.

Models With Wet-Type Grids: Series F1 electromagnetic separators for processing dry granular materials and powders can be equipped with stainless steel grids normally used for processing liquids, slurries and gases. Matrices comprised of wet-type grids have many times the cumulative length of collecting edges of matrices equipped with the vane-type grids. With a unique assembly of grids and a different vibration pattern, moderately free-flowing dry materials including powders can be more effectively processed. A single pass through a matrix of wet grids is equivalent to several passes through a matrix of vane-type grids.