The S.G. Frantz Series F1E Electromagnetic Separators provide economical, improved performance in separating fine ferromagnetic particles. They are ideal for the industrial processing of liquids, slurries, and gases under difficult processing conditions and higher product temperatures (up to 400°F (205°C)).

QUALITY MATERIALS AND PROVEN PIPELINE DESIGN

Our Series F1E Electromagnetic Separators are assembled using the following product-contact parts:

- All metallic contact parts (with the exception of the pole pieces and matrices — see below) are made of type 303 and 304 stainless steel

- Pole pieces and standard matrices composed of highly ferromagnetic type 430 stainless steel (crimped to provide uniform open spaces and spiral wound flat ribbon, then nickel-brazed)

- Optional compressed type 430 stainless steel wool matrices in several grades (for magnetic filtration of low-viscosity liquids and vapors containing no particles larger than 50 microns)

They utilize a pipeline design, with an inlet pipe connection at the center bottom and a discharge pipe connection at the side, near the top. This requires that flow be controlled from outside the unit to ensure uniform low-velocity flow through the matrix (working pressure not to exceed a maximum of 150 psi*).

HIGHER BACKGROUND MAGNETIC FIELDS

Background magnetizing fields measured in the empty separating chamber (with pole pieces, but without the matrix in place) are at least 1,500 oersteds, more than 50% above that of models in the F1 series. With the matrix in place, the background field is substantially above 1,500 oersteds, inducing a field several times more intense in the collecting elements.

The high-field energy gradient H(dH/dX) at the collecting edges of a standard matrix element fabricated of steel ribbon .25″ in width and 0.02″ thick is estimated as 5.0 x 1011 gauss2/cm, assuming that the field induced in the steel near the edge is about 5,000 gauss as calculations indicate.

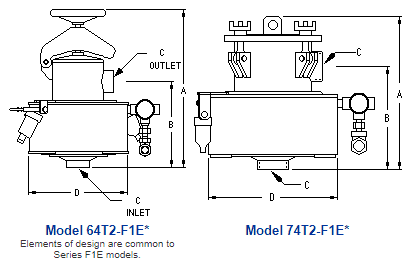

2 DIFFERENT MODELS TO HANDLE YOUR CAPACITY NEEDS

The primary differences between the 64T2-F1E and 74T2-F1E models relate to capacity, with the former able to process up to 650-2,000 GPH (2,460-7,570 LPH) and the latter able to process 1,300-4,000 GPH (4,921-15,140 LPH).

| Height Overall (A) | Height to Outlet (B) | Inlet & Outlet (C) | Diameter of Body (D) | Current @ 115 V dc | Capacity, Heavy Slurries | Net Weight | Shipping Weight | |

|---|---|---|---|---|---|---|---|---|

| Model No. | Inches Centimeters | Amps | U.S. GPH LPH | Pound Kilograms |

||||

| 64T2-F1E | 28.50 72.4 | 15.25 38.7 | 3.00 7.6 | 14.00 35.6 | 7.4 | 650-2,000 2,460-7,570 | 265 120 | 305 138 |

| 74T2-F1E | 25.30 64.3 | 17.00 43.2 | 4.00 10.2 | 21.00 53.3 | 10.5 | 1,300-4,000 4,921-15,140 | 730 331 | 930 422 |

| All models require a continuous flow of clean, low-dissolved-solids cooling water, at approximately 2 gpm, and minimum pressure differential of 30 psi. | ||||||||

*Separators designed for higher working pressures and temperatures with ASME Code Division VIII, Section 1 pressure vessels are also available.

Contact us today to learn more about S.G. Frantz or any of our Electromagnetic, Permanent Magnet, and/or Laboratory Separators.