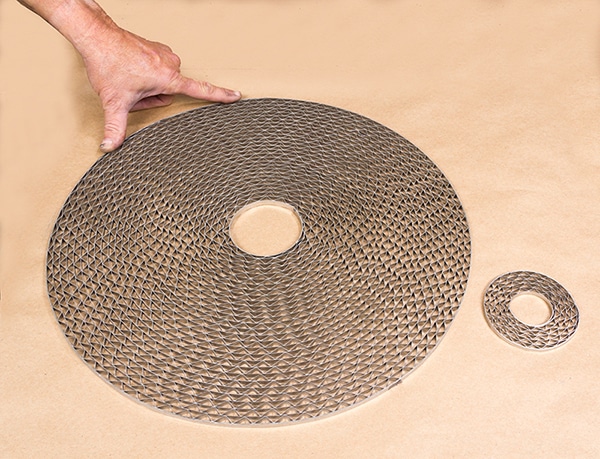

Our Series F2 Electromagnetic Separators for Dry Materials are designed for separating fine ferromagnetic particles present as 1% (weight) or less of the material to be processed. The standard vane-type grids are normally utilized for dry material separation. However, for moderately free-flowing materials, we can manufacture a unit that utilizes the same proprietary grids normally used for wet separations. Matrices comprised of wet-type grids have many times the cumulative length of collecting edges than those found in vane-type grids, allowing for better separation. With a unique assembly of grids and a different vibration pattern, such materials can be more effectively processed. A single pass through a matrix of wet grids is equivalent to several passes through a matrix of vane-type grids.

Magnetic background fields measured in the empty separating space (with pole pieces, but without the matrix in place) are approximately 2,500 gauss. The average background magnetizing field measured in the separating chamber with the pole pieces and matrix in place is 3,790 gauss, more than three times the background field intensity of the F1 units. Magnetic fields at the matrix edges, where separation occurs, are nearly 23,000 gauss at the upper edges of the vanes and over 19,500 gauss at their lower edges.

HOW THE F2 ELECTROMAGNETIC SEPARATOR FOR DRY MATERIALS WORKS

- Material is fed into a hopper or hub.

- Material is processed through a stack of alternately inclined parallel grids, pouring over each vane onto the face of the grids below (if wet-type grids are used, the material is processed straight through, pouring over multiple edges).

- Collecting edges attract and hold the ferromagnetic particles.

- Material is discharged through the bottom hub (on both units).

TYPICAL APPLICATIONS FOR OUR F2 DRY MATERIAL SEPARATORS

Our F2 Dry Materials Electromagnetic Separators are commonly used in Ceramics • Pharmaceuticals • Chemicals • Food Processing • Health and Beauty • Any Dry Granular Material or Powder

F2 ELECTROMAGNETIC SEPARATOR FOR DRY MATERIALS SPECIFICATIONS

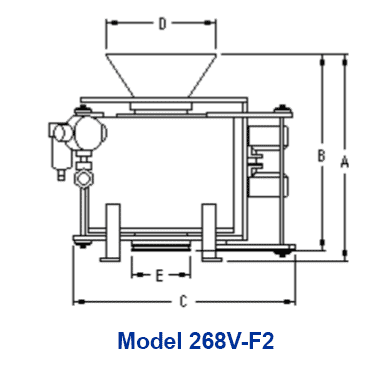

| Model 248V-F21 Inches Centimeters | Model 268V-F21 Inches Centimeters |

||

|---|---|---|---|

| Height Overall | (A) | 22.50 57.2 | 31.50 80.0 |

| Height of Separator | (B) | 18.50 47.0 | 28.50 72.4 |

| Width, Maximum | (C) | 28.00 71.1 | 38.00 96.5 |

| Feed hopper Diameter | (D) | 12.00 30.5 | 18.00 45.7 |

| Outlet Diameter | (E) | 3.25 8.3 | 6.75 17.1 |

| Capacity2 | Ft3 /hour Meters 3 /hour | Ft3 /hour Meters 3 /hour |

|

| 5-40 0.14-1.13 | 25-200 0.7-5.7 |

||

| Coil current at 115 Volts D.C. | Amperes D.C. | Amperes D.C. | |

| 30 | 50 | ||

| Vibrator motor, 230/460 Volts A.C., 50/60 Hertz, 3 phase | Horsepower | Horsepower | |

| 1/10 | 1/6 | ||

| Weight | Pounds Kilograms | Pounds Kilograms |

|

| Net | 510 231 | 1460 662 |

|

| Shipping | 550 249 | 1550 703 |

|

| Notes 1. Explosion proof versions of models conforming to the above specifications are available. Explosion proof models are manufactured to comply with requirements for equipment for use in CLASS I, DIVISION 1, GROUP D Hazardous locations and CLASS II, DIVISION 1, GROUPS E, F, G dust ignition-proof indoor locations. Explosion-proof models are not certified by any independent testing laboratory. 2. Processing capacity varies with material characteristics such as particle size and shape, specific gravity, moisture content, etc. |

|||

Contact us today to learn more about S.G. Frantz or any of our Electromagnetic, Permanent Magnet, and/or Laboratory Separators.