About Us

About Us

Quality

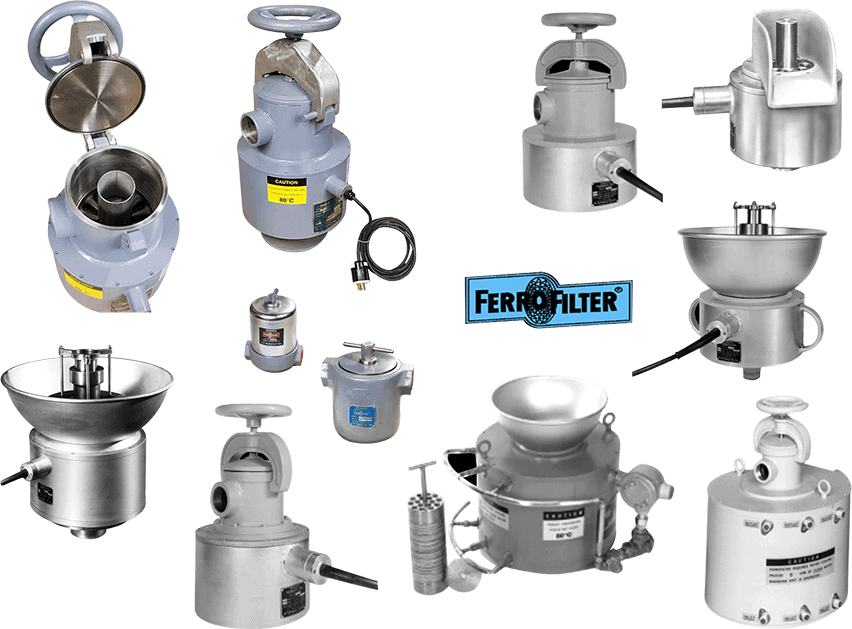

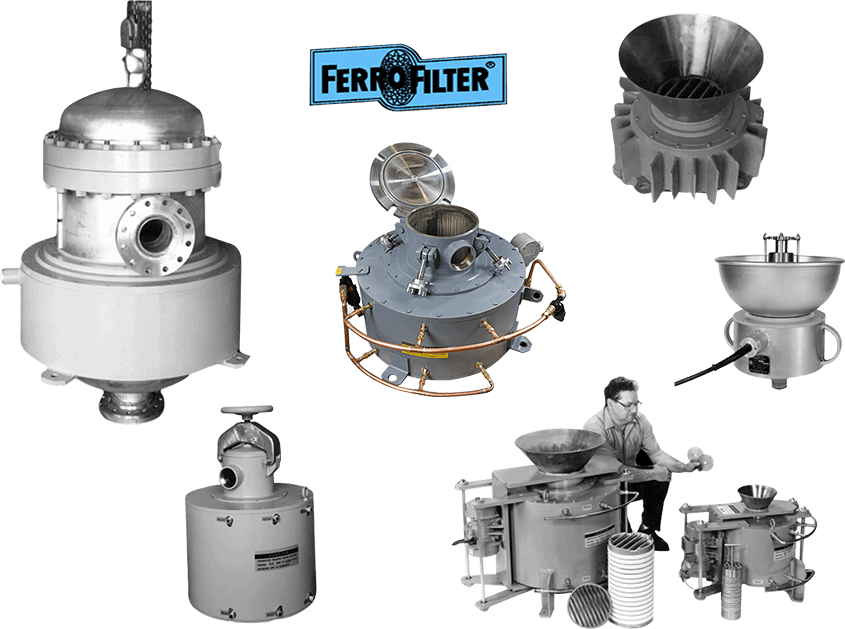

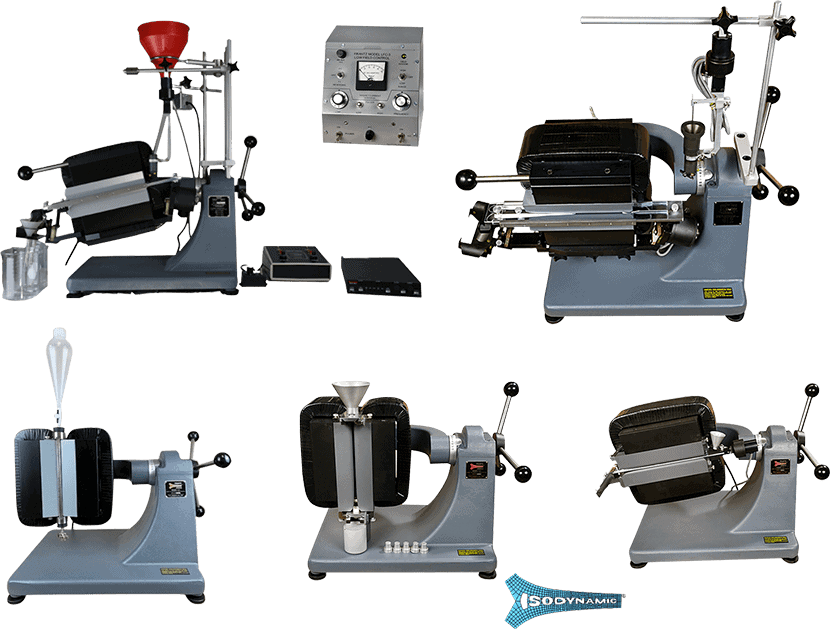

S.G. Frantz’s singular focus on excellence enables production of the industry’s most effective Magnetic Separators, earning them a reputation for exceptional quality and lasting performance.

Customer Focus

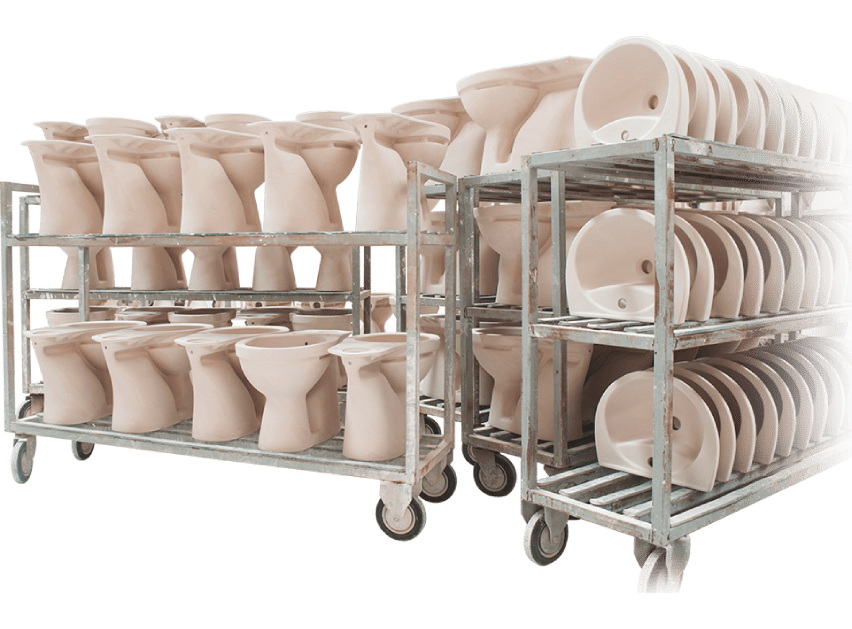

S.G. Frantz’s mission has always been to provide high-performance magnetic separators for the most diverse industrial applications and environments. This mission is realized by adhering to a detailed QA process and individual customer service practices.

Lifetime Technical Support

S.G. Frantz’s offers remote lifetime technical support.

Our Products Span The World…and We Are Not Done Yet!

We offer our product lines to every country allowed by US Export Laws and Regulations.

Countries Our Products Lines Are Offered

- Australia

- Papua New Guinea

- New Zealand

Countries Our Products Lines Are Offered

- Canada

- Costa Rica

- Dominican Republic

- Guatemala

- Jamaica

- Mexico

- Nicaragua

- Puerto Rico

- Virgin Islands

Countries Our Products Lines Are Offered

- Argentina

- Bolivia

- Brazil

- Chile

- Colombia

- Ecuador

- Guyana

- Peru

- Uruguay

Countries Our Products Lines Are Offered

- Bangladesh

- China

- India

- Indonesia

- Iran

- Israel

- Japan

- Jordan

- South Korea

- Kuwait

- Laos

- Lebanon

- Malaysia

- Oman

- Pakistan

- Philippines

- Russia

- Saudi Arabia

- Singapore

- Sri Lanka

- Thailand

- Turkey

- United Arab Emirates

- Yemen

Countries Our Products Lines Are Offered

- Cote d’Ivoire

- Democratic Republic of the Congo

- Egypt

- Eritrea

- Liberia

- Libya

- Madagascar

- Morocco

- Mozambique

- Nigeria

- Senegal

- Sierra Leone

- South Africa

- Tanzania

- Togo

- Tunisia

- Burkina Faso

- Zimbabwe

Countries Our Products Lines Are Offered

- Albania

- Austria

- Belgium

- Bulgaria

- Croatia

- Czech Republic

- Denmark

- Estonia

- Finland

- France

- Germany

- Greece

- Hungary

- Ireland

- Italy

- Luxembourg

- Netherlands

- Norway

- Poland

- Portugal

- Rumania

- Slovenia

- Spain

- Sweden

- Switzerland

- United Kingdom

- Yugoslavia